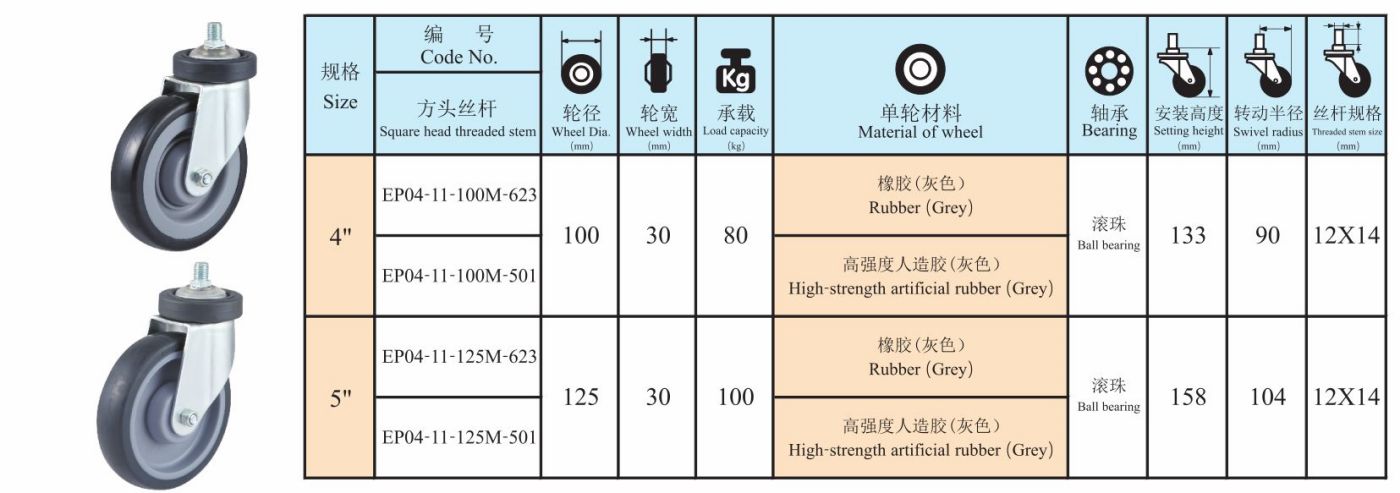

5 Nti Lub Taub Hau Trolley PU Supermarket Castor Log EP4 Series Square taub hau threaded qia hom

1. Cov ntaub ntawv zoo siab yuav nrog kev kuaj xyuas zoo.

2. Txhua yam khoom tau soj ntsuam nruj me ntsis ua ntej packing.

3. Peb yog cov chaw tsim khoom rau ntau tshaj 25 xyoo.

4. Kev txiav txim mus sib hais lossis kev txiav txim sib xyaw raug lees txais.

5. OEM xaj tau txais tos.

6. Kev xa khoom sai.

7) Txhua hom casters thiab lub log tuaj yeem hloov kho.

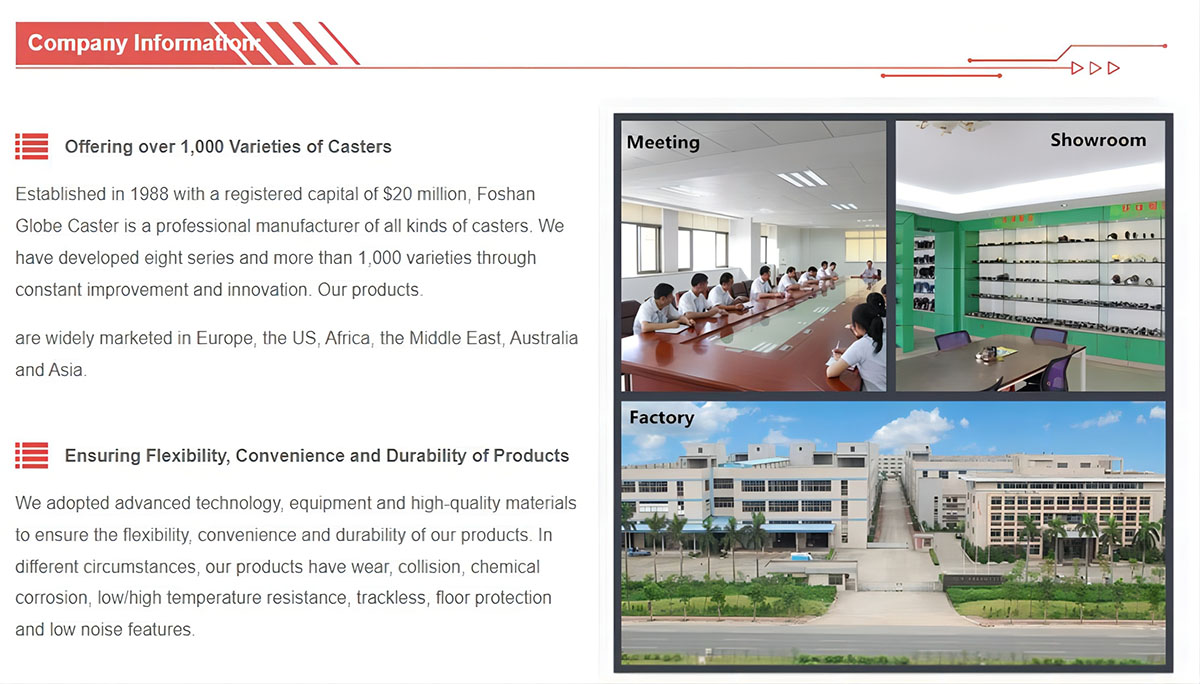

Peb tau txais kev siv thev naus laus zis, khoom siv thiab cov ntaub ntawv zoo los xyuas kom meej qhov yooj, yooj yim thiab kav ntev ntawm peb cov khoom.Nyob rau hauv cov xwm txheej sib txawv, peb cov khoom muaj hnav, kev sib tsoo, tshuaj lom neeg corrosion, qis / siab kub kuj, trackless, pem teb tiv thaiv thiab tsis tshua muaj suab nrov nta.

Kev sim:

Rhiav:

Txhua tus paub tias electroplating yog txheej txheem tseem ceeb heev rau casters, tab sis vim li cas casters yuav tsum tau electroplated?Dab tsi yog lub luag haujlwm ntawm electroplating ua si rau casters?Tom ntej no, Globe Caster yuav muab cov lus qhia ntxaws ntxaws rau koj.

Dab tsi yog caster plating

Thaum cov casters yog electroplated, cov hlau plated lossis lwm yam khoom siv tsis sib haum yog siv los ua cov anode, thiab cov khoom hlau yuav tsum tau plated yog siv los ua cathode.Cov cations ntawm cov hlau plated raug txo rau ntawm cov hlau nto los ua ib txheej.Txhawm rau tshem tawm cov kev cuam tshuam ntawm lwm cov cations thiab ua kom cov txheej txheej tsis sib xws thiab ruaj khov, nws yog ib qho tsim nyog yuav tsum siv cov tshuaj uas muaj cov txheej txheem hlau cations li caster electroplating tov kom cov concentration ntawm txheej hlau cations tsis hloov.Lub hom phiaj ntawm caster electroplating yog phaj hlau txheej ntawm lub substrate los hloov cov khoom nto los yog qhov ntev ntawm lub substrate.Caster electroplating tuaj yeem txhim kho corrosion kuj ntawm cov hlau (cov hlau txheej yog feem ntau corrosion-resistant hlau), nce hardness, tiv thaiv puas, thiab txhim kho cov conductivity Performance, lubrication, kub kuj, thiab zoo nkauj nto.

Lub luag haujlwm ntawm caster plating

Ib lub tshuab siv electrolysis los tso cov hlau txheej nrog adhesion zoo tab sis cov khoom sib txawv ntawm cov khoom siv hauv cov khoom siv tshuab.Lub caster electroplating txheej yog sib xws ntau tshaj li kub dip txheej, feem ntau thinner, xws li los ntawm ob peb microns mus rau kaum ntawm microns.Los ntawm caster electroplating, koj tuaj yeem tau txais kev tiv thaiv zoo nkauj thiab ntau yam kev ua haujlwm saum npoo ntawm cov khoom siv tshuab, thiab tuaj yeem kho cov hnav thiab ua haujlwm ua haujlwm.Cov txheej txheej feem ntau yog ib qho hlau lossis hlau, xws li lub hom phiaj titanium, zinc, cadmium, kub lossis tooj dag, tooj liab, thiab lwm yam;kuj tseem muaj cov txheej txheem dispersion, xws li nickel-silicon carbide, nickel-graphite fluoride, thiab lwm yam.;tseem muaj cov khaubncaws sab nraud povtseg, xws li steel Cov tooj liab-nickel-chromium txheej, nyiaj-indium txheej ntawm cov hlau, thiab lwm yam. Ntxiv nrog rau cov hlau-raws li cam khwb cia hlau, hlau thiab stainless hlau, lub hauv paus khoom ntawm caster electroplating muaj xws li tsis -ferrous hlau, xws li ABS yas, polypropylene, polysulfone thiab phenolic yas, tab sis yas casters yuav tsum tau ua tshwj xeeb ua kom thiab rhiab heev kev kho mob ua ntej electroplating.

Globe Caster them sai sai rau qhov tseem ceeb ntawm electroplating hauv cov txheej txheem ntau lawm.Nyob rau tib lub sijhawm, nws muaj kev tswj xyuas tiav thiab cov txheej txheem sab hauv.Cov khoom raug xa los ntawm kev soj ntsuam ze.Cov neeg muas zaub tau txais tos kom xaj txhua yam ntawm cov casters.